When it comes to PCB assembly, flexible circuits offer a host of benefits, but they need to be assembled by an experienced PCB assembly service.

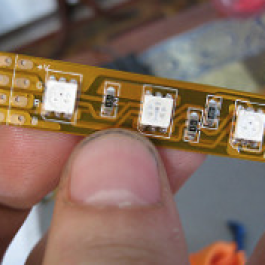

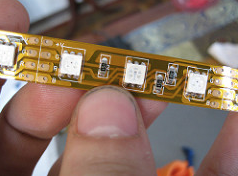

Flexible circuits – also called flex circuits or flexible PCBs – can be defined as a pattern of conductive traces bonded onto a flexible substrate. Most flex circuits are passive wiring structures used to interconnect electronic components (such as resistors, capacitors, integrated circuits, etc.). However, some flexible PCBs are only used to make interconnections between other electronic assemblies, either directly or with connectors. When it comes to PCB assembly, flexible circuits offer a host of benefits.

Features of a PCB Assembly Flexible Circuit

- Conforms to small spaces and contoured shapes

- Carries electronic signals and power

- Similar properties to a printed circuit board but a flexible structure

- Eliminates or enables the use of smaller, less expensive connectors

- Shields radiated noise for EMI (electro-magnetic interference)

- Provides mechanical flexing

Benefits of Flexible Circuits in PCB Assembly

- Mechanical and electrical repeatability

- Cost savings – typically 30% compared to hand wiring

- Space savings – typically 60%

- Assembly savings

- Reliability improvements

- Wiring errors eliminated

- Can bend, fold, and twist, unlike traditional printed circuit boards

Flexible Circuits are Just as Durable as Hardboards

It is a common misconception that greater rigidity translates to greater durability. However, a properly designed flex circuit will last just as long as a PC board. Durability is a function of use, and flex circuits that are repeatedly bending experience more stress than a board that simply lies flat. Therefore it can be argued that flex circuits are in fact more durable than their hardboard counterparts. Flexible circuits have been used in the automotive, aerospace, medical and industrial industries for decades with outstanding results.

Telan Offers Experienced PCB Assembly of Flexible Circuits

There is a nearly endless number of material combinations that can go into a flex circuit. When choosing the materials that best meet the functional needs of the board, there are a number of factors to consider, including:

- Capacitance

- Chemical and mechanical resistance

- Current

- Type of flexing

- Temperature extremes

It takes an experienced team to assemble a flex circuit according to your specifications. With over 35 years of experience in PCB assembly, flexible circuits are a standard part of Telan’s assembly services. Our state-of-the-art equipment and facilities can accommodate all your PCB assembly needs, from box builds and flex circuits to turnkey and prototype services. If you are looking for a reliable PCB assembly service to produce your flexible circuits, call Telan today at 215-997-7603.